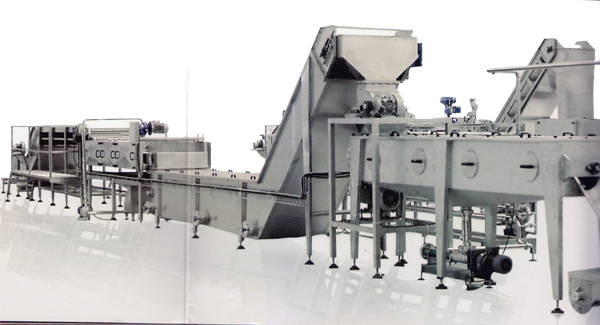

Bana Processing Line

Innovative technological cycle assuring a reduction of costs & a superior quality:

- Ripening control system

- Receiving, washing & pre-selection system

- Chamfering & peeling system. mechanical-automatis & at modified atmosohere

- Refining system at modified atmosphere

Multi Fruit Extraction Line

This is a versatile line whose technological cycle can be used to process any quality of fruit:

- Receiving & pre-selection system

- Washing system by immersion, brushing or both

- Extraction system patented for garnting an excellent yield & quality

- Enzymatic treatment assuring the highest consistency

- Purée or juice refining system

- Solid/liquid separation system

Pineapple Extraction Line

Excellent yield, high adaptability to every quality of pineapple, reduced maintenance cost:

- Receiving,pre-selection & washing systems

- Exclusive peeling system, automatic-tangential & at constant thickness

- Enzymatic treatment

- Juice extraction system combined with finisher & continous press

- System for pulp content regulation & dot separation

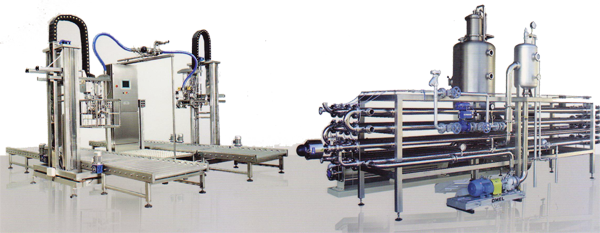

Aseptic Sterilizing & Filling Lines

Different models of heat exchangers suitable for any type of prduct; aseptic fillers of essential design, compact & easy to operate & clean:

- De-areating system with aroma condenser

- Homogenising system

- Exchangers at multiple tube for products at low viscosity

- Exchangers at concentric tube in tube for products at high viscosity

- Exchangers at large passage for products in pieces

- Exchangers at scraped surface for products at high content of sugar or fat

- Aseptic fillers for high & low acid products

- Structure for packages by 5 & 1,000L

- Suitable for spot by 1'' or 2''

- Automatic control systems of washing, sterilising & production cycles

|